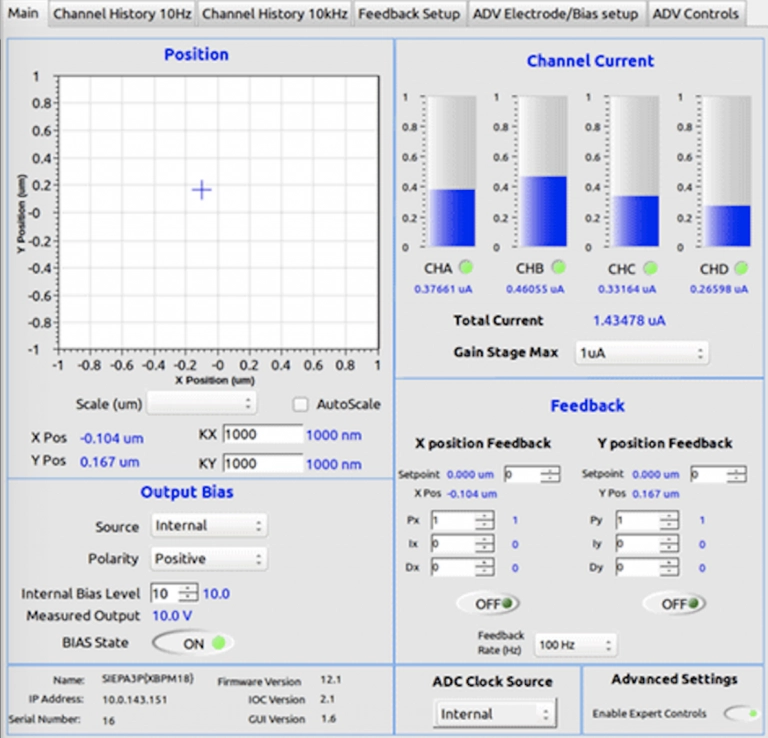

With Sydor’s software, users can pair peripheral equipment such as mirrors for easy beam position correction in the event of a deviation. The system has a full software suite with pre-programmed calibration routines.

The electrometer’s channels have five programmable gain stages, including 20 pA-1 μA, 0.5 μA-10 μA, 5 μA-100 μA, 50 μA-2 mA, and 1 mA-35 mA. The electrometer can run in both an EPICS or Tango environment.

Sydor’s Advanced Electrometer combines high performance 4- channel electrometer readouts with integrated DAC outputs for feedback control of mirrors, stages, or other beam positioning elements. The device can be located in close proximity to key components, sensitive signals, and control loops. The Advanced Electrometer includes an output bias voltage to complete a position control package that is ideal for pairing with Sydor’s four quadrant Diamond Beam Position Monitors (DBPMs).

Depending on the user’s setup, the Advanced Electrometer can also operate in a relative or absolute calibrated manner. The embedded proportional–integral–derivative (PID) loops can be tuned for feedback control against user-specified ranges of drift or offset. This functionality automates correction for beam movement or drift, and can maintain nanometer precision over hours of experimental operation.

The data is sampled at 378 kS/s and feeds back into your mechanical system, enabling 10 Hz closed-loop operation. The system software sampling can be setup for single shot or continuous measurement modes. The channels have five programmable gain stages and a large 18-bit dynamic range to allow maximum signal amplification without saturating. The electrometer is sensitive to currents from 20 pA to 35 mA.

The system can be linked to a host PC running EPICS or TANGO IOC for ease of integration into larger systems. The software GUI is tailored to allow intuitive monitoring of raw current signals. Collected data can be displayed as plotted raw data or auto-scaled depending on the signal intensity. Cumulative channel currents can also be displayed.

The Sydor Advanced Electrometer can be used to produce accurate beam positioning feedback for a beam positioning control system by acquiring precise current measurements from a number of devices and diodes.

Advanced Electrometer Features

- Precise readout and output control for four channels with integrated ultrastable bias output

- Embedded DAC outputs to link to feedback devices. Full featured PID allows calibration and fast feedback control at nanometer precision

- User-friendly software to visualize the readout, control, and trends of the process

Applications

- Controls KB mirrors, focusing elements, stages, and other beam stability mechanical control elements

- Useful for setup, monitoring, and troubleshooting

- Provides comparison of calibrated beamline elements against collected readout values

Product Specifications

Electrometer Specifications

Readout: Internal electrometer module

Readout Channels: 4

Current Measuring Range: 20 pA to 35 mA

Gain Selection: 5 programmable gains, (20 pA-1 μA, 0.5 μA-10 μA, 5 μA-100 μA, 50 μA-2 mA,1 mA-35 mA)

Data Rate: 378 kS/s, customizable up to 1.1 MHz

Resolution Bits: 18

Bias Voltage Output: -40 VDC to +40 VDC (internal and external)

Current Polarity: Bipolar

Readout

I/O Control Ports: 1 Ethernet, 4 DAC LEMO Outputs (-10 to +10 VDC), 6 SFP (transreceiver not included), 2 LEMO LVDS (IN), customizable operation, 2 LEMO LVDS (OUT), customizable operation

Control Interface: 10/100/1000 Ethernet TCP/IP, UDP

External Bias Input/ADC Clock Connector: SMA/LEMO

Electrometer Input/Bias Output Connectors: Triaxial

Mechanical

Enclosure: 19″ 2U Rack Mount

Main Interface

Data Waveforms

Inquiry - Sydor Advanced Electrometer